I recently purchased Smooth-On’s sortaclear 40 for a project i have been working on. I spent at least a week getting my model ready. Starting with a 3d print of the object, i then sanded and smoothed the abs and filled, primed, and painted the object. I was finally ready to make my mold and spent another day figuring out the best possible way to set up the sprues and vents. Then it came down to pouring my silicone. I degassed the mixture and poured it perfectly, no air entrapment. It was beautiful. I then used my pressure chamber to cure the mold.

After 20 hours of curing, I found that it set up great, But i could see a gap between the model and the silicone. I opened it up to see if anything touching the model surface did not cure. After all my forethought and planning, I didn’t even question whether or not my surface would inhibit the silicone.

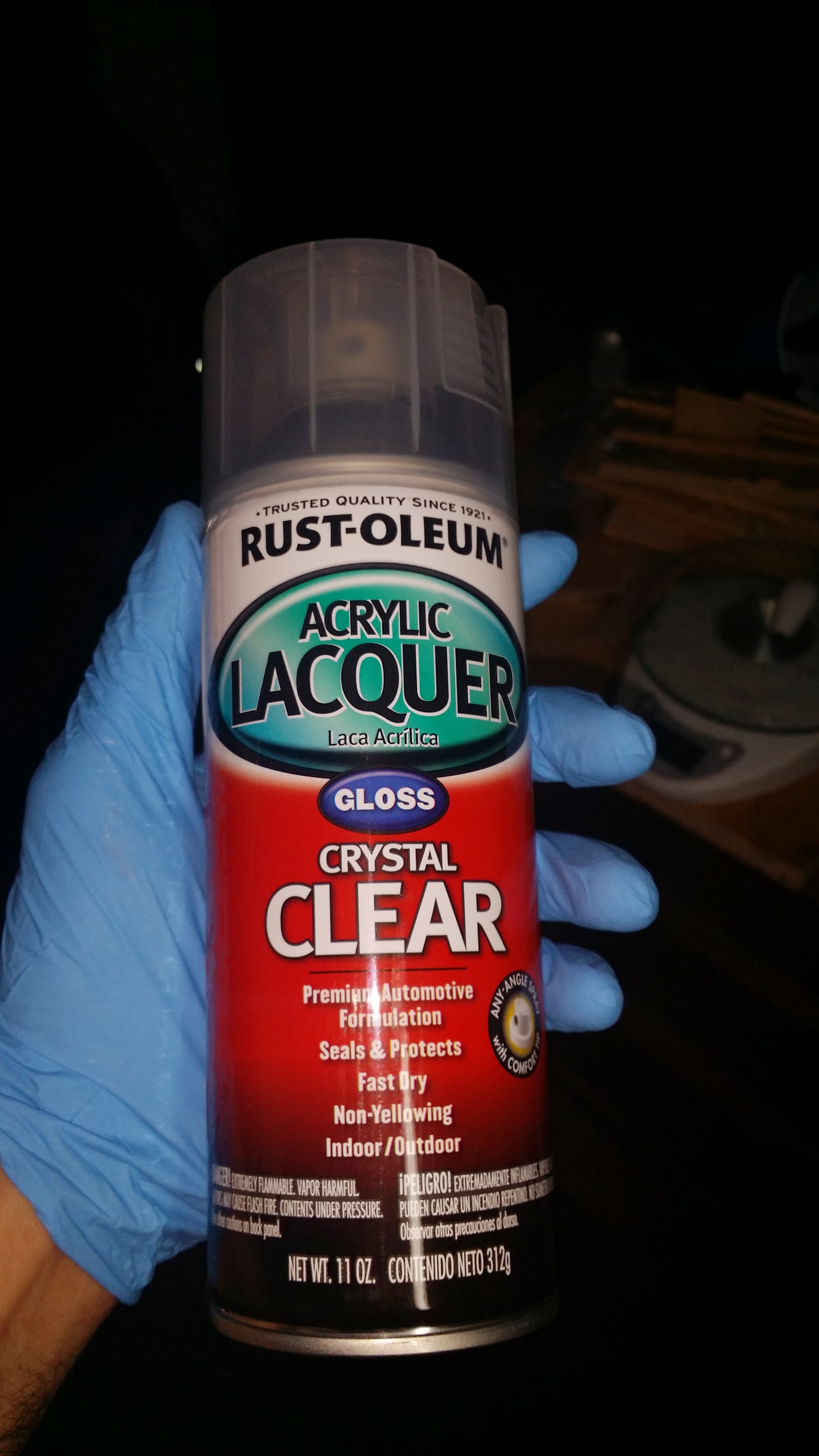

After reading the information for the silicone. I saw that they recommend sealing your model with an acrylic lacquer. I searched at every store I could think of to find a matte finish clear acrylic lacquer, and could only find a gloss clear lacquer.

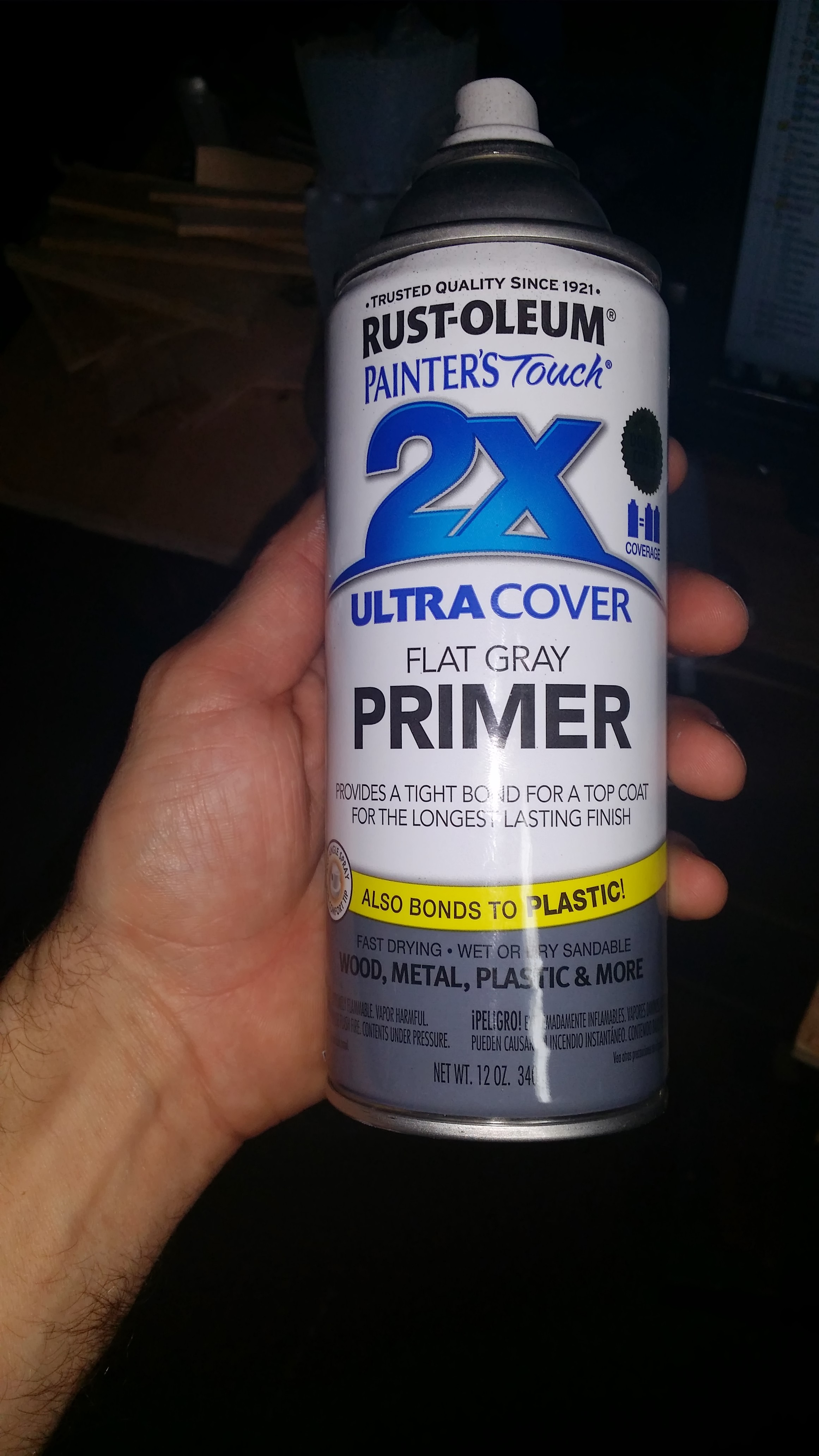

You can purchase acrylic lacquer at most auto supply stores. I also found one product at hobby lobby that is a matte acrylic, but not a lacquer. Rustoleum sells acrylic lacquer at auto zone and probably other auto supply stores. I have also found that duplicolor has an entire line of acrylic paints, but I couldnt find exactly what I needed for this project.

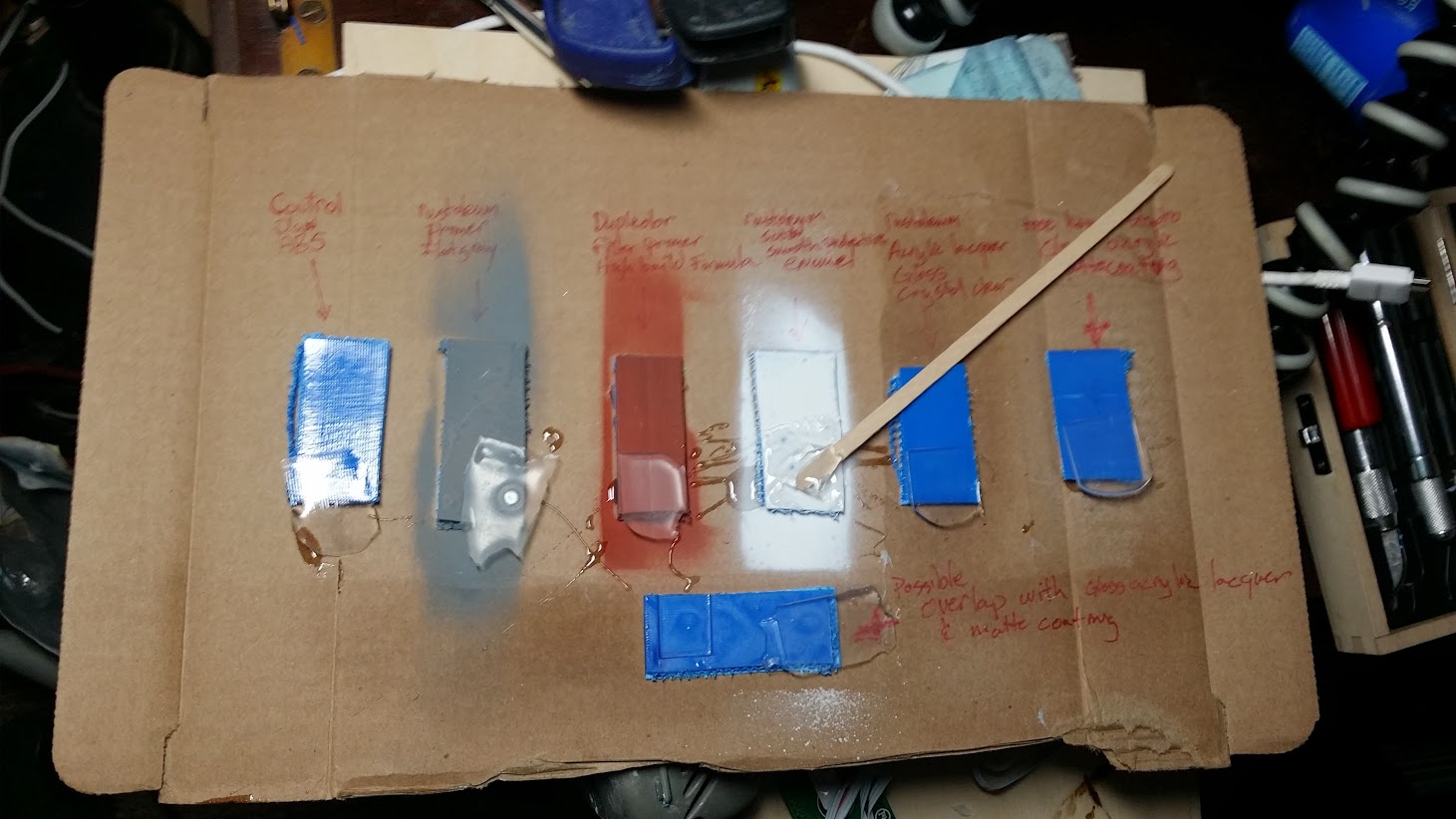

Because I want to make sure that this works before I waste another pound or so of silicone, I am going to do a test on all of the products that I have used so far in my model as well as adding the two other products I have purchased.

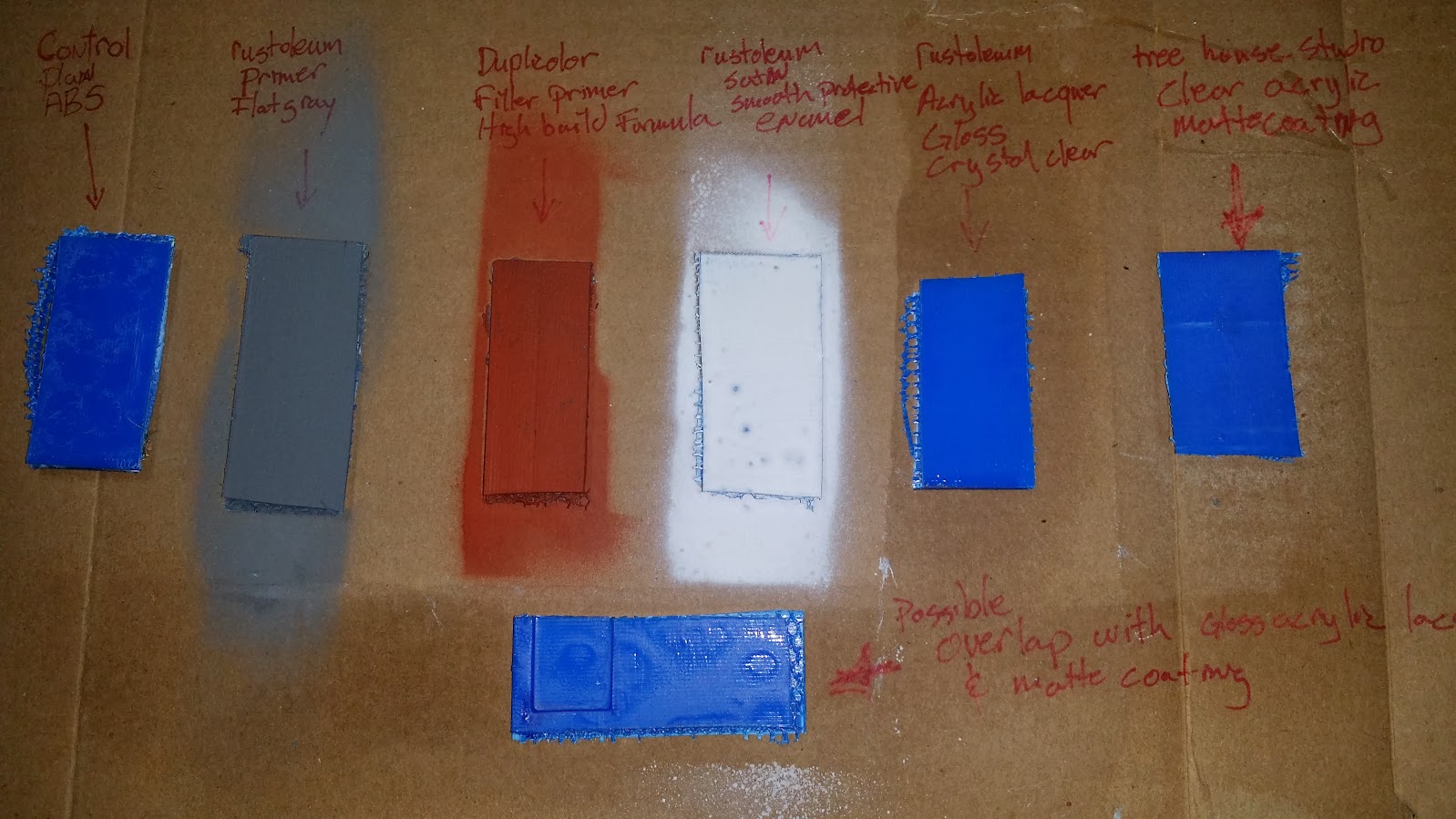

Here are the products used in this test:

gallery:

The test is laid out from left to right and then one object on the bottom of the page.

1. Plain abs

2. Rustoleum flat gray primer

3. Duplicolor filler primer. High build formula

4. Rustoleum smooth protective enamel

5. Rustoleum acrylic lacquer. Crystal clear gloss

6. Tree House Studio clear acrylic matte coating

7. Rustoleum acrylic lacquer. Crystal clear gloss on the first coat and Tree House Studio clear acrylic matte coating on top. I want a matte finish, so maybe if I seal with the gloss acrylic lacquer and then coat with the matte acrylic, it will not react. But just in case I need to test this before wasting mass material.

Here are the pieces, covered with the silicone rubber, before curing.

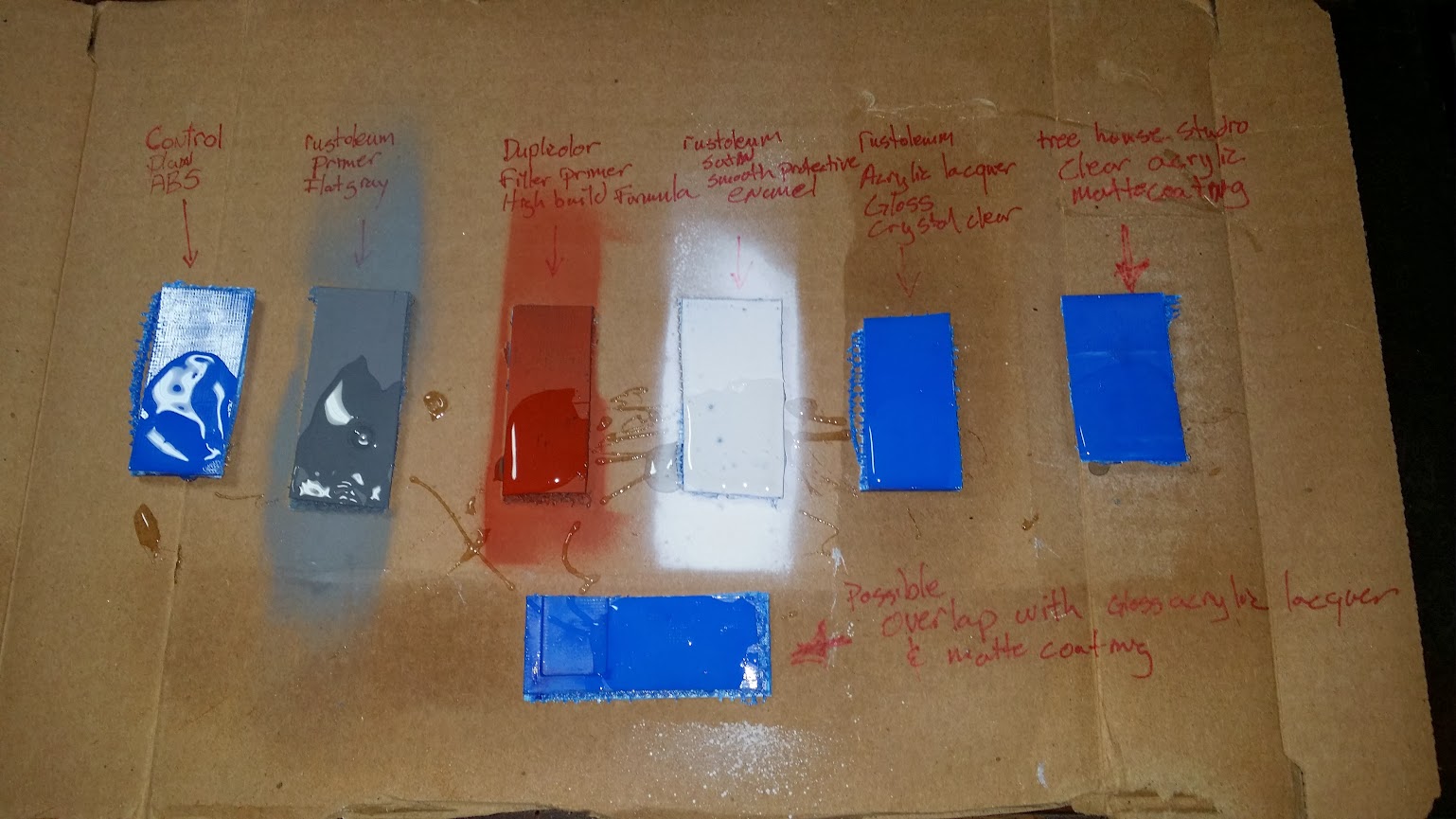

And finally, the pieces after curing.

As you may be able to tell from the photo, the only one to inhibit the curing of Smooth-On sorta clear 40 was the Rustoleum smooth protective enamel.

I do not know if this contains any sulfur, but I know that it should not be used with your silicone molds.

The ones that did work

1. Rustoleum flat gray primer

2. Duplicolor filler primer. High build formula

3. Rustoleum acrylic lacquer. Crystal clear gloss

4. Tree House Studio clear acrylic matte coating

The combination of the clear and the matte also cured fine. The abs worked as well. But I did that as a control, just in case.

(UPDATE) just a note to people who would like to be able to clean their master model. Use rubbing alcohol. It may eat away at some of the paint, but you’re going to have to remove that anyway.

Leave a comment